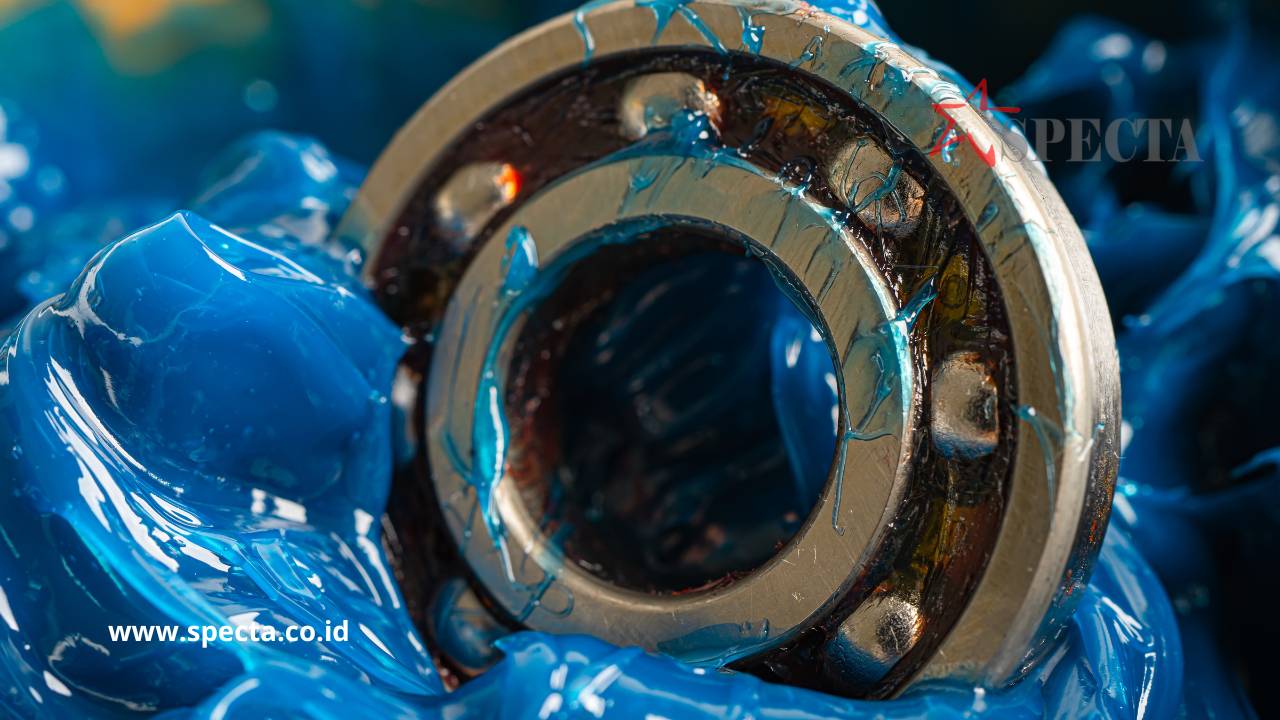

In industrial applications, choosing the right lubricant can significantly affect machinery efficiency and lifespan. Whether you’re operating in extreme cold or blazing heat, selecting the appropriate grease is crucial for maximizing productivity and minimizing maintenance costs. This article dives deep into the performance of Panaoil Grease Specta, focusing on its versatility and performance across a range of temperatures. We’ll explore its features, advantages, and why it is an industry favorite, especially for maintaining efficiency in challenging environments.

1. Introduction to Industrial Grease

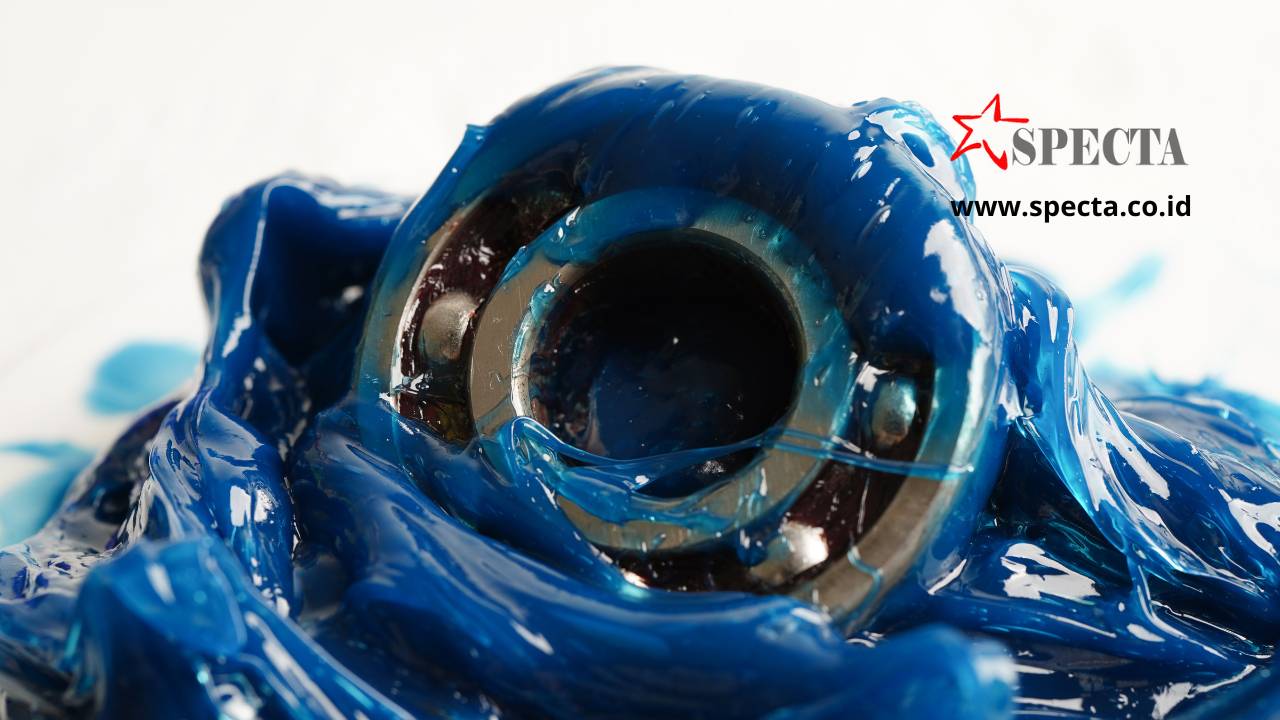

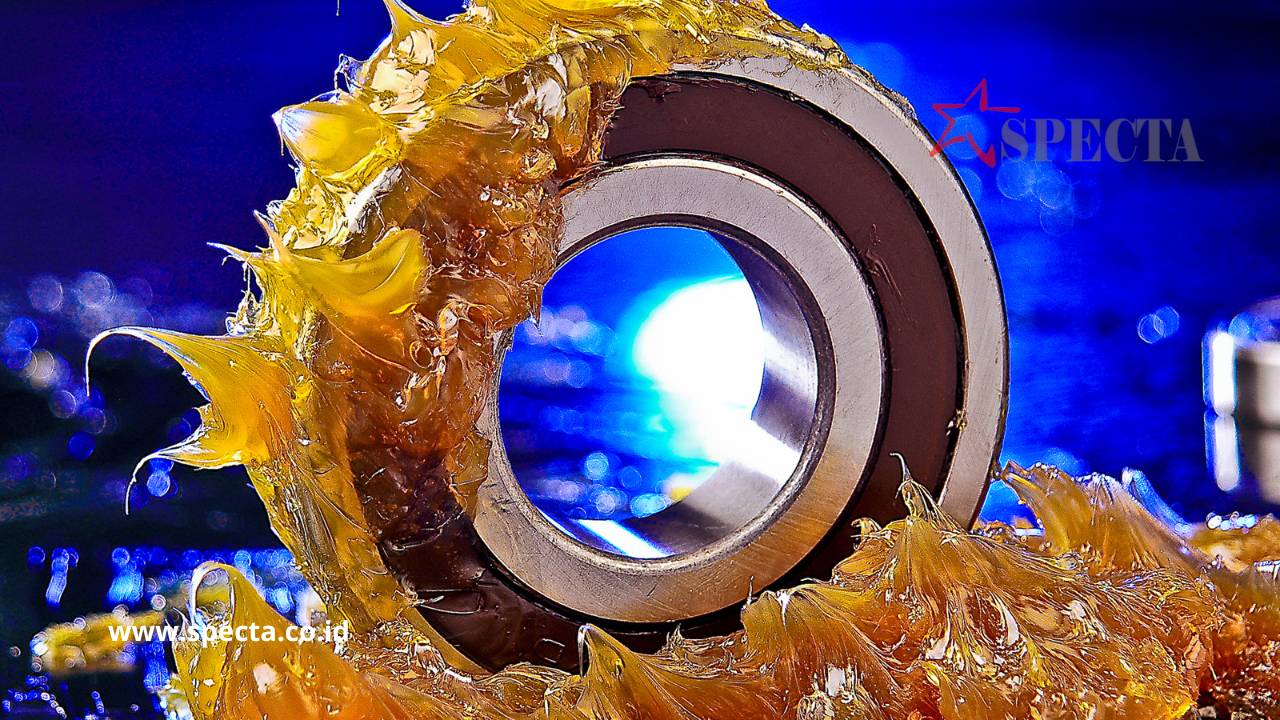

Industrial grease is essential for the proper functioning of mechanical components. A high-quality grease prevents friction, reduces wear, and offers a barrier against contaminants such as dust, water, and dirt. The role of grease becomes even more critical when machines are exposed to extreme temperature changes, as the wrong lubricant can lead to severe equipment failures.

This is where Panaoil Grease Specta comes into the picture. Developed with cutting-edge technology, this grease is engineered to offer outstanding performance across various temperature ranges, ensuring your machinery runs smoothly even under demanding conditions.

2. What is Panaoil Grease Specta?

Panaoil Grease Specta is a premium quality multi-purpose grease designed for use in a wide variety of industrial applications. It contains a unique blend of additives and thickening agents, which gives it the capability to handle both high and low temperatures effectively. The grease is primarily formulated to provide:

- Excellent high-temperature stability

- Superior water resistance

- Reliable oxidation stability

- High load-carrying capacity

The advanced formulation of Panaoil Grease ensures that it meets the demanding requirements of today’s high-performance machinery, keeping components running efficiently while reducing wear and tear.

3. Why Temperature Matters

Temperature is a key factor in determining the effectiveness of any industrial lubricant. When temperatures fluctuate beyond the capabilities of ordinary greases, machinery can be prone to severe damage. Here’s why selecting temperature-appropriate grease is important:

- Low Temperatures: The grease needs to have adequate fluidity so that it can be pumped and reach all moving parts.

- High Temperatures: The lubricant must resist oxidation and evaporation. If it fails to do so, it may break down and leave behind deposits that can impede mechanical motion.

With its broad operating temperature range, Panaoil Grease Specta is engineered to handle diverse climates, from the icy cold of winter to the scorching heat of summer, without compromising performance.

4. Panaoil Grease Specta in Cold Temperature Applications

Operating in cold temperatures can present significant challenges, as many greases thicken and lose their ability to flow effectively. However, Panaoil Grease Specta is designed with a base oil that maintains excellent fluidity even in freezing conditions.

- Low Starting Torque: The ability of Panaoil Grease Specta to provide a low starting torque means that equipment requires less energy to get moving, even when exposed to sub-zero temperatures. This characteristic is particularly advantageous for machinery that operates outdoors or in refrigerated environments.

- Pumpability: One of the standout features of Panaoil Grease Specta is its ease of pumpability at low temperatures, which ensures that it can be distributed efficiently through automated lubrication systems.

5. Performance at High Temperatures

Operating machinery in high-temperature environments requires grease that can withstand intense heat without breaking down. Panaoil Grease Specta excels in these conditions, offering excellent thermal stability and oxidation resistance.

- Thermal Stability: This grease can handle continuous temperatures as high as 200°C without losing consistency or degrading. This makes it ideal for equipment operating in hot environments such as steel mills, foundries, and power generation facilities.

- Reduced Evaporation: Unlike traditional greases that tend to evaporate at elevated temperatures, Panaoil Grease has a formulation that ensures low evaporation rates, which means longer lubrication intervals and less frequent re-application.

6. Water Resistance: A Key Benefit of Panaoil Grease Specta

In industrial settings, machinery is often exposed to moisture and even direct water sprays. Panaoil Grease Specta has excellent resistance to water washout, which helps maintain lubrication under wet conditions.

- Water Washout Test Results: In tests that simulate exposure to heavy water sprays, Panaoil Grease Specta has shown superior performance in retaining its properties and staying in place where other greases fail.

- Application Examples: This water resistance makes it particularly suitable for industries like marine, agriculture, and food processing where moisture is a regular challenge.

7. Friction Reduction and Wear Protection

Reducing friction is one of the primary roles of any grease, and Panaoil Grease Specta excels at minimizing the effects of metal-to-metal contact.

- Load Carrying Capacity: The grease is formulated with additives that boost its load-carrying capacity, providing an extra layer of protection for bearings and gears.

- Extreme Pressure (EP) Additives: These additives help in maintaining lubrication even under high-stress conditions, reducing the chances of component failure and extending the life of your machinery.

8. Compatibility with Different Materials

When selecting a grease, it’s crucial to consider the types of materials it will interact with. Panaoil Grease Specta is compatible with a wide range of sealing materials, ensuring that it does not degrade seals or cause leakage.

- Compatibility Test: Tests indicate that the grease works well with commonly used materials like nitrile, viton, and other synthetic rubbers, making it highly versatile for different equipment designs.

9. Applications of Panaoil Grease Specta

Panaoil Grease Specta is versatile and used across several industries, including:

- Automotive: Ideal for wheel bearings, chassis, and universal joints.

- Heavy Equipment: Suitable for excavators, bulldozers, and cranes that require reliable performance under heavy loads.

- Manufacturing: Perfect for conveyors, motors, and gearboxes used in industrial production lines.

The versatility of Panaoil Grease Specta is unmatched, providing reliable lubrication in environments that demand high performance.

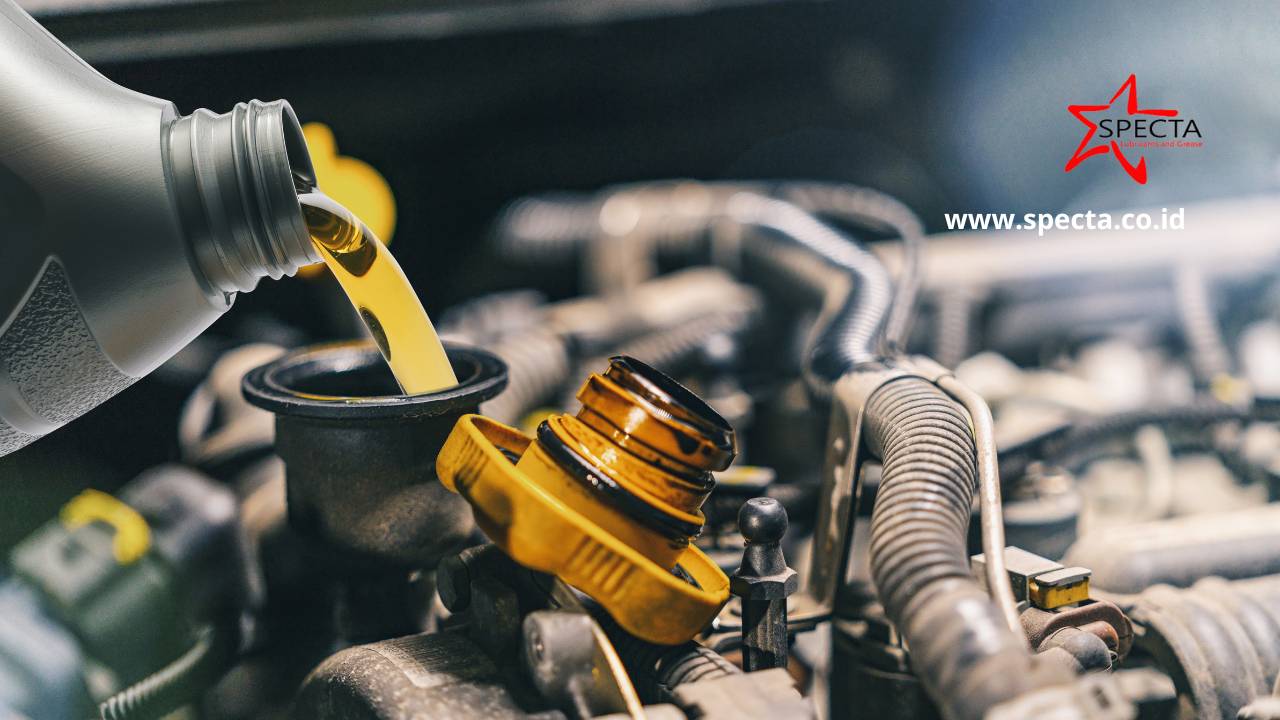

10. How to Apply Panaoil Grease Specta for Best Results

- Clean the Surface: Before applying grease, always clean the surfaces to remove contaminants that may affect performance.

- Use Proper Tools: Use a grease gun or automated system to apply the correct amount.

- Monitor Usage: Check grease levels periodically to determine when a reapplication is necessary.

Proper application and regular maintenance will help you get the most out of Panaoil Grease Specta, ensuring machinery remains in excellent working condition.

Read more also: Panaoil Market Data: Global Sales Volume Trends and Market Share Insights

11. Environmental Considerations

Panaoil Grease Specta is formulated to be environmentally friendly. It has a reduced environmental footprint compared to many other industrial greases.

- Biodegradability: The components are designed to degrade naturally, causing less harm if spilled in sensitive environments.

- Non-toxic: The grease is non-toxic, making it safer to handle during routine maintenance operations.

12. Advantages of Choosing Panaoil Grease Specta

- Longer Equipment Life: Reduces wear, helping extend the lifespan of components.

- Reduced Maintenance Costs: Less frequent lubrication means cost savings over time.

- Versatility: Suitable for a wide range of industries and applications.

13. FAQs About Panaoil Grease Specta

Q1: What is the operating temperature range for Panaoil Grease Specta?

A1: Panaoil Grease Specta can operate effectively between -40°C and 200°C, making it suitable for both cold and hot environments.

Q2: Can Panaoil Grease Specta be used for automotive applications?

A2: Yes, it is highly effective for automotive applications, including wheel bearings, chassis, and universal joints, due to its extreme pressure additives and excellent temperature stability.

Q3: How does Panaoil Grease Specta perform in wet conditions?

A3: Panaoil Grease Specta has excellent water washout resistance, making it ideal for applications exposed to moisture or water spray.

Q4: Is Panaoil Grease Specta safe for the environment?

A4: Yes, Panaoil Grease Specta is formulated with environmentally friendly components and is non-toxic, making it a safer option for both operators and the environment.

Q5: What types of machinery can benefit from using Panaoil Grease Specta?

A5: Panaoil Grease Specta is versatile and can be used for a range of equipment including heavy machinery, automotive components, and industrial manufacturing systems.

Q6: Does Panaoil Grease Specta help reduce operational costs?

A6: Absolutely. Its ability to perform under extreme conditions and resist breakdown reduces maintenance requirements and downtime, leading to lower operational costs.

Q7: How often should Panaoil Grease Specta be applied?

A7: The reapplication interval depends on the working conditions and equipment type. Regular checks should be conducted to ensure optimum grease levels.

14. Conclusion: Panaoil Grease Specta – The Ideal Choice for All Temperatures

The performance of Panaoil Grease Specta across a wide temperature range makes it an ideal choice for various industrial applications. From automotive to heavy equipment, Panaoil Grease Specta ensures machinery runs smoothly while providing excellent protection against wear, friction, and moisture. By choosing Panaoil Grease Specta, businesses can ensure long-lasting protection, reduced maintenance costs, and peak performance even in the most challenging environments.

Ready to elevate your machinery’s performance with Panaoil Grease Specta? Get in touch today to find out more about how it can meet your lubrication needs and ensure your machinery keeps running smoothly under any conditions.