Selecting the right industrial oil for your machinery is critical for ensuring optimal performance, reducing wear, and extending the lifespan of your equipment. With various types of oils and countless formulations available in the market, making the right choice can seem overwhelming. In this guide, we’ll explore the essential factors to consider when choosing the right oil for your machines and how it impacts their operation and efficiency.

1. Understand the Types of Industrial Oils

There are different types of industrial oils available, each suited for specific applications. Knowing the differences between these oils can help you match the right one to your machinery:

a. Mineral Oils

Derived from crude oil through refining, mineral oils are the most basic type of industrial oil. They are suitable for general use and cost-effective, but they may not perform as well in extreme conditions.

b. Synthetic Oils

Synthetic oils are chemically engineered to offer superior performance in extreme temperatures and demanding environments. They are more stable, last longer, and provide better protection but come at a higher cost compared to mineral oils.

c. Semi-Synthetic Oils

Semi-synthetic oils combine both mineral and synthetic oils. These blends offer a balance between affordability and enhanced performance, making them ideal for moderate industrial conditions where full synthetic oils aren’t necessary.

d. Biodegradable Oils

As environmental regulations tighten, biodegradable oils are gaining popularity. These oils break down naturally and are less harmful to the environment. While they may not offer the same level of protection as synthetic oils, they are perfect for industries with a focus on sustainability.

2. Consider the Operating Environment

Your machinery’s operating environment plays a significant role in the type of oil you should choose. For example:

- High-Temperature Environments: Equipment used in high-temperature conditions, such as foundries or manufacturing plants, will benefit from oils with high thermal stability, such as synthetic oils. These oils are designed to maintain their viscosity and resist oxidation even at extreme temperatures.

- Cold Climates: Machinery operating in cold environments needs oil with excellent low-temperature fluidity. In this case, synthetic oils, which perform better at low temperatures, can prevent oil thickening and ensure smooth operation.

- Wet or Humid Conditions: If your machines operate in wet or humid conditions, look for oils with water-repellent properties to avoid rust and corrosion. Anti-corrosion additives and hydraulic oils formulated to resist water contamination are excellent choices.

3. Check the Viscosity Requirements

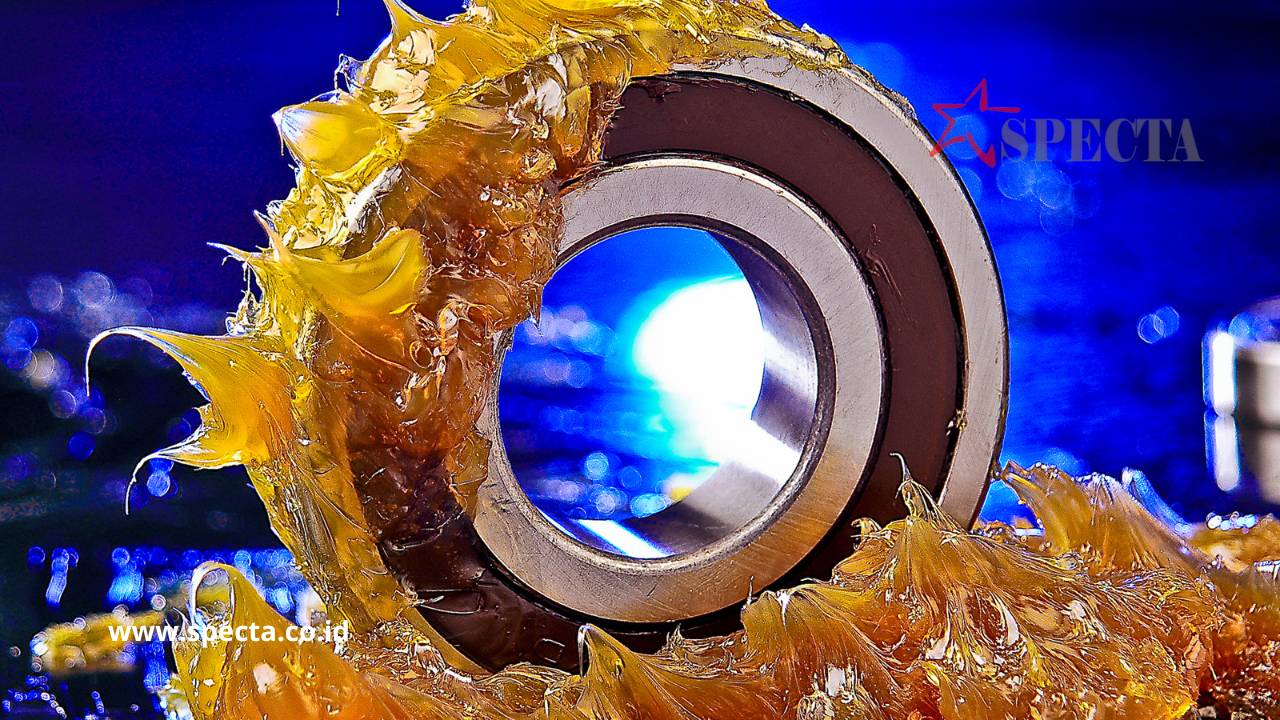

Viscosity is one of the most critical factors in selecting the right industrial oil. It refers to the thickness of the oil and its ability to flow at different temperatures. The correct viscosity ensures that the oil will adequately lubricate your machine components, reducing friction and wear.

- Low Viscosity Oils: These are thinner oils that flow easily, making them suitable for high-speed applications where heat dissipation is essential.

- High Viscosity Oils: These thicker oils are better for heavy-duty applications where slow-moving parts require more cushion to prevent metal-to-metal contact.

Most machinery manufacturers specify the recommended oil viscosity range in the equipment manual, so always refer to it when selecting an oil.

4. Consider the Load and Pressure on the Machinery

The type of load and pressure your machinery experiences also determines the best oil for the job. For example:

- Heavy Loads: For machines under heavy loads, such as gearboxes or hydraulic systems, look for oils with extreme pressure (EP) additives. These additives provide an extra layer of protection by preventing metal surfaces from wearing down.

- High-Speed Machines: In high-speed applications, such as turbines or compressors, oils with excellent heat dissipation and anti-foaming properties are critical. Look for oils designed for high-speed environments that can handle rapid heat build-up without losing effectiveness.

5. Use Oil Additives for Enhanced Performance

Oil additives are chemical compounds added to industrial oils to improve specific performance characteristics. Depending on the type of machinery, the environment, and the demands of the application, additives can significantly enhance oil performance.

Here are some common oil additives and their benefits:

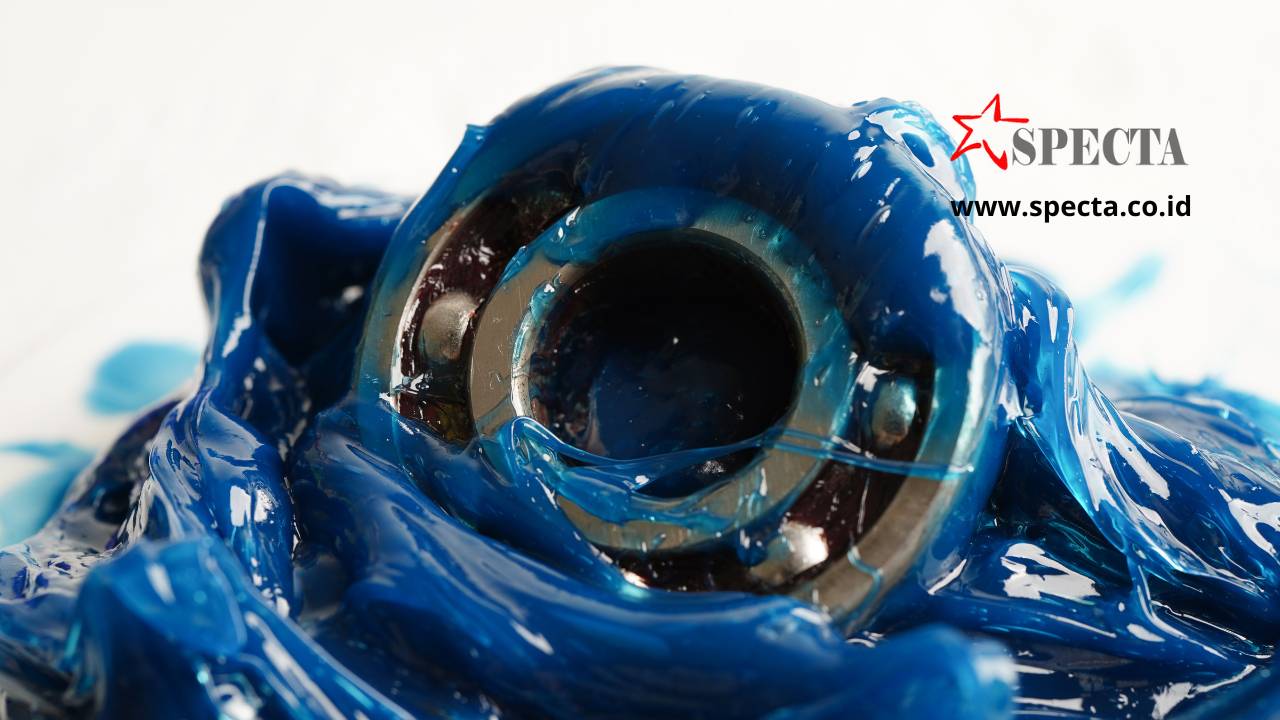

- Anti-Wear Additives: These additives create a protective film on machine surfaces, reducing wear and extending the life of machine components.

- Corrosion Inhibitors: Prevent metal components from rusting, especially in wet or humid environments.

- Viscosity Improvers: Help maintain the oil’s viscosity across a wide temperature range, ensuring optimal lubrication under varying conditions.

- Detergents and Dispersants: Keep the engine or machine components clean by preventing the build-up of sludge, varnish, or other contaminants.

- Oxidation Inhibitors: Prevent oil from breaking down due to exposure to air and high temperatures, extending the oil’s service life.

6. Match the Oil to the Specific Machinery Application

Not all oils are created equal, and different machines require different lubrication needs. Here’s a breakdown of common industrial machinery and the recommended oil types for each:

- Hydraulic Systems: Use hydraulic oils that offer anti-wear protection and resist water contamination. Look for oils with excellent demulsification properties to separate water from the oil and maintain system efficiency.

- Gearboxes: Gear oil with extreme pressure (EP) additives is essential for protecting gear teeth under high load. Gear oils with anti-foaming agents also help prevent excess air from being trapped in the oil, ensuring smooth operation.

- Compressors: For air and gas compressors, use compressor oils that offer good thermal stability and oxidation resistance. These oils help prevent carbon deposits and extend the compressor’s life.

- Turbines: Turbine oils need to resist high temperatures and oxidation. Look for oils that offer excellent anti-foam and anti-wear properties, particularly for turbines in power generation or other critical applications.

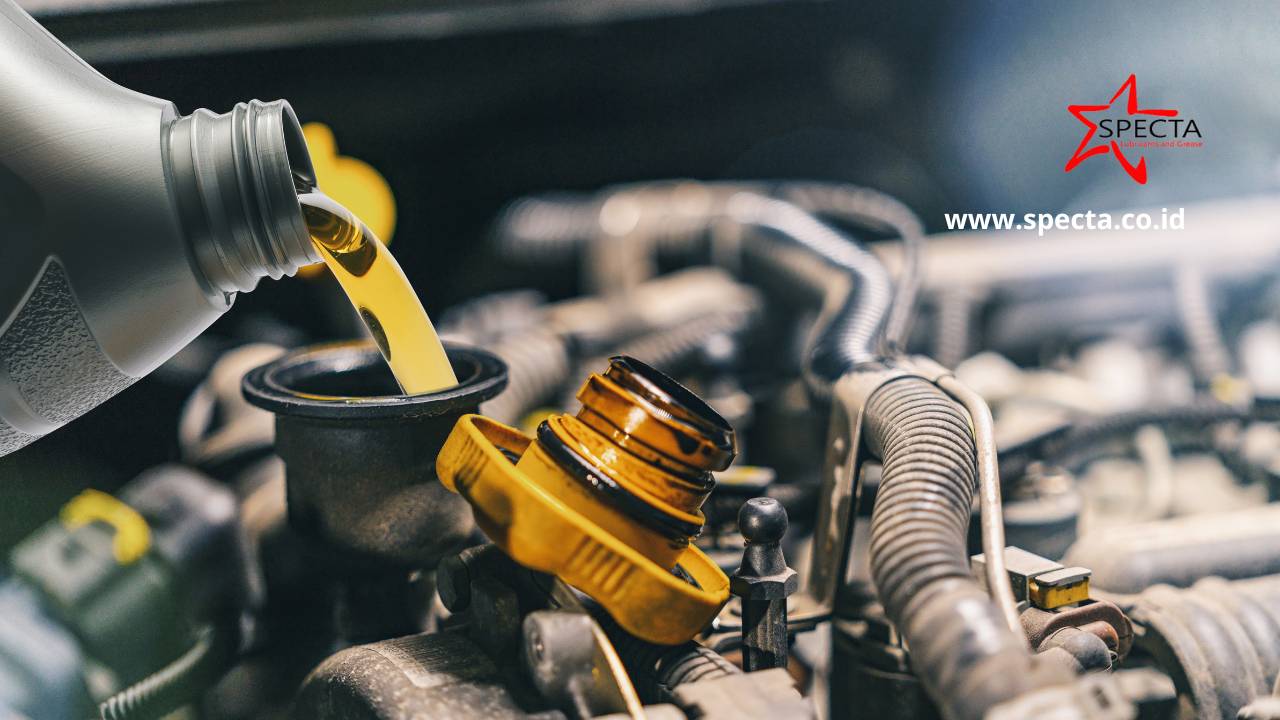

- Engines: Engines in industrial settings often run continuously under heavy loads. Engine oils with high detergency and dispersancy are necessary to keep internal components clean and prevent deposit formation.

7. Factor in Oil Change Intervals

One of the biggest mistakes companies make is not changing oil frequently enough, which leads to increased wear and tear. The right oil, combined with timely oil changes, can extend the life of machinery significantly. Here’s how to determine oil change intervals:

- Monitor Oil Condition: Use oil analysis to monitor the condition of your oil over time. By testing the oil, you can detect contamination, oxidation, and the presence of metal particles that indicate wear.

- Follow Manufacturer Guidelines: Always follow the oil change intervals recommended by the machine manufacturer. For more critical machinery or extreme environments, consider shortening the intervals to ensure optimal protection.

8. Environmental and Regulatory Considerations

In industries where environmental impact and regulatory compliance are important, biodegradable oils are a valuable option. These oils break down naturally, reducing the risk of environmental contamination in case of spills or leaks.

Moreover, some industries are subject to strict regulations regarding oil disposal. Using biodegradable oils or oils with low environmental impact can help meet compliance standards and minimize waste management costs.

Frequently Asked Questions (FAQ)

1. How do I know which industrial oil to choose for my machinery? Choosing the right oil depends on several factors, including the machine type, operating environment, load, and manufacturer recommendations. Always refer to the equipment manual for specific oil viscosity and additive requirements.

2. Why is oil viscosity important for my machinery? Viscosity ensures that the oil flows properly within the machinery, reducing friction and wear between moving parts. The correct viscosity also helps with heat dissipation and overall machine efficiency.

3. Can I use the same oil for different machines? While some oils may be versatile, it’s not always advisable to use the same oil for different machines. Each machine has specific lubrication needs, and using the wrong oil can result in poor performance or even damage.

4. How often should I change industrial oil? Oil change intervals depend on the type of oil, machine usage, and operating conditions. Refer to the manufacturer’s guidelines, but regular oil analysis can also help determine the optimal change frequency.

5. What are the benefits of using synthetic oils over mineral oils? Synthetic oils offer better performance at extreme temperatures, improved protection against wear, longer oil life, and better overall machine efficiency. However, they are more expensive than mineral oils.

6. Are biodegradable oils suitable for all machinery? Biodegradable oils are best suited for industries focused on environmental sustainability or operating in areas with strict environmental regulations. While they may not perform as well in extreme conditions as synthetic oils, they offer adequate protection for general use.

7. What role do oil additives play in industrial machinery? Oil additives improve specific properties of the oil, such as anti-wear protection, oxidation resistance, and viscosity stability. The right additives can enhance machine performance, reduce wear, and extend oil change intervals.

8. Is it possible to mix different types of industrial oils? In general, mixing oils with different formulations or additives is not recommended, as it can compromise the oil’s performance and the machine’s protection. Stick to the manufacturer’s recommendations and avoid mixing oils whenever possible.

9. How can oil analysis help in maintaining machinery? Regular oil analysis helps detect contamination, metal particles, or oxidation that could signal wear or oil degradation. It can help you identify potential problems early and adjust your oil change intervals for maximum machine efficiency.

By following this comprehensive guide, you’ll be well-equipped to choose the right industrial oil.

Read more also: Industrial Oils and Everything You Need to Know for Maximum Efficiency