Gas Engine Oil for Industrial Machinery: Maximizing Efficiency

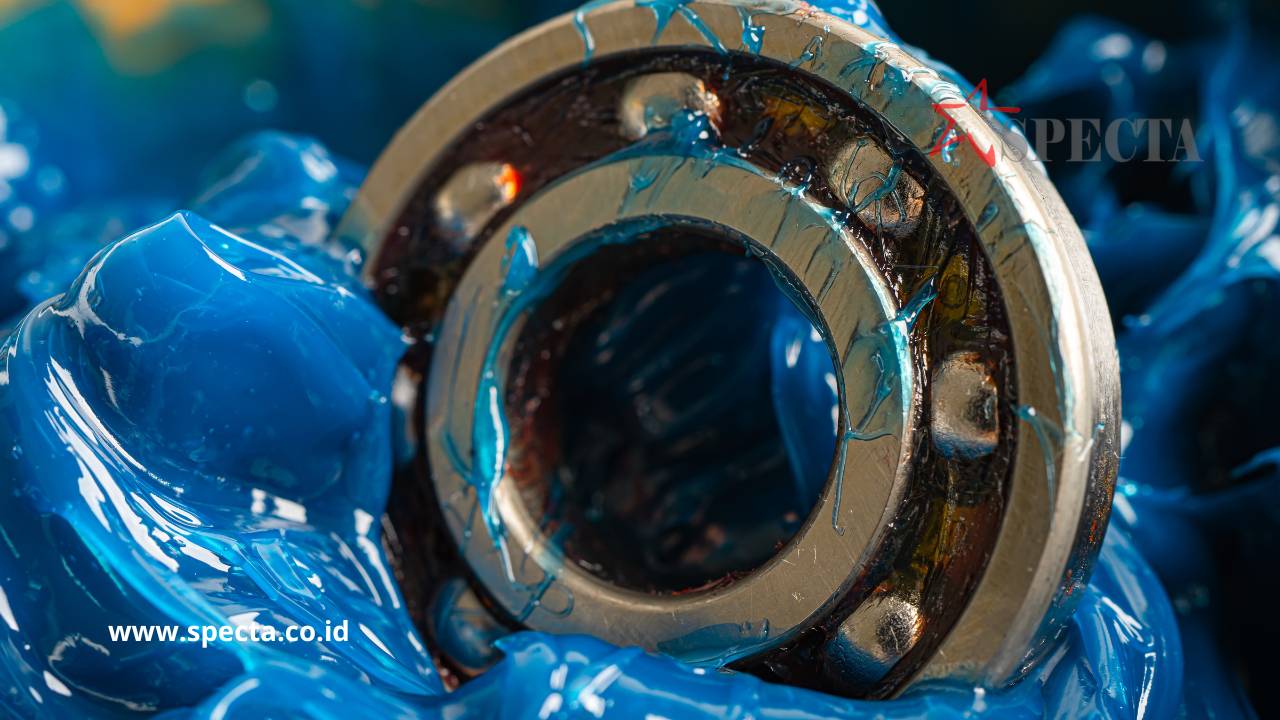

When it comes to maintaining the efficiency of industrial machinery, the selection of the right gas engine oil is crucial. This comprehensive guide explores how gas engine oil, particularly the Panaoil brand, plays a vital role in the longevity and performance of gas-powered industrial engines. Let’s delve into why gas engine oil is preferred, how it works in industrial settings, and the benefits you can reap.

Why Use Gas Engine Oil for Industrial Machines?

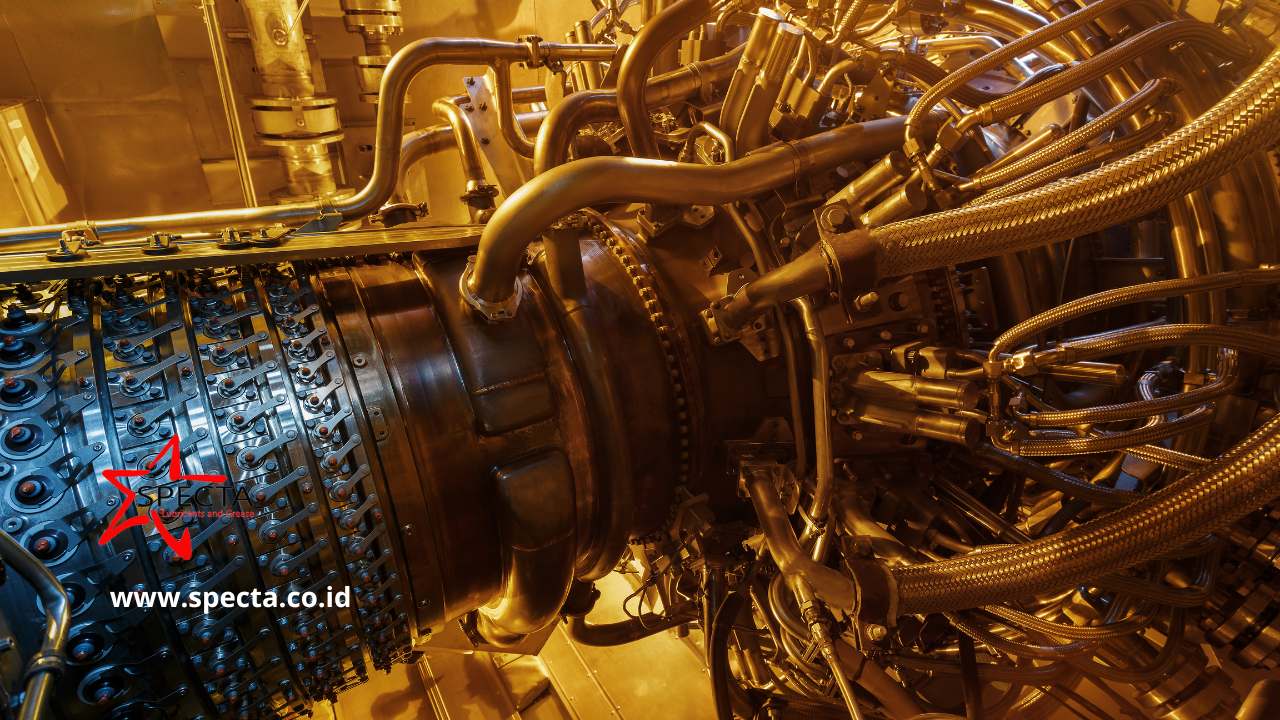

Gas engine oil is specifically designed to protect, lubricate, and improve the performance of engines powered by natural gas or other similar gaseous fuels. In an industrial context, gas engines are often used to power compressors, pumps, or generators, making oil selection critical for minimizing wear and ensuring reliability.

Key Benefits of Using Gas Engine Oil in Industrial Applications

- Heat Management: Industrial gas engines tend to generate significant amounts of heat due to their size and heavy-duty cycles. Gas engine oil is formulated to efficiently manage this heat, preventing engine components from getting too hot and deteriorating prematurely.

- Clean Combustion: Gas engine oil helps maintain a cleaner engine by reducing the formation of carbon deposits, sludge, and other contaminants. This feature is especially crucial in industrial settings where engines run for extended hours without a break.

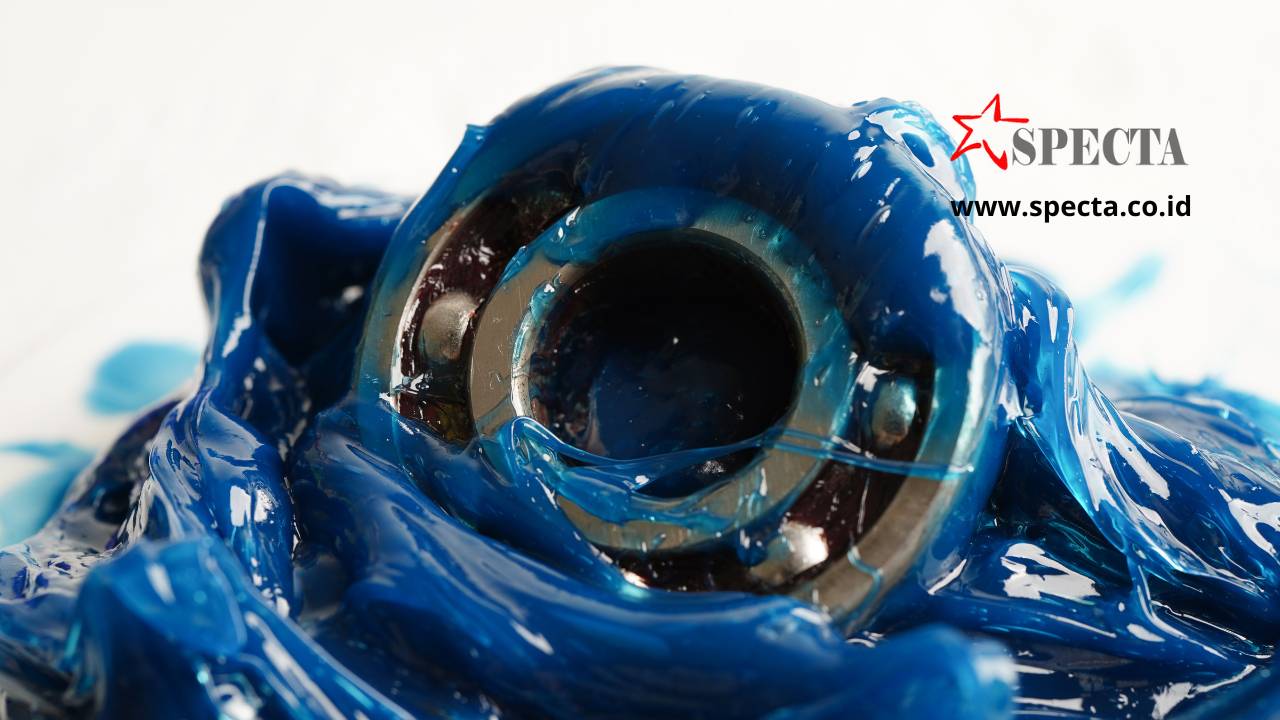

- Enhanced Durability: Using gas engine oil ensures the durability of moving components in industrial engines. Since these engines often face tough environments, oil that prevents excessive friction and wear becomes indispensable.

- Emissions Control: Gas engine oil can help reduce harmful emissions from industrial engines. With increasing regulatory pressure on emissions control, choosing the right oil helps comply with emissions standards, creating a safer work environment and less impact on the environment.

Choosing the Right Gas Engine Oil for Industrial Use

Selecting the right gas engine oil can make the difference between efficient operation and repeated engine failures. Here are some aspects to consider when choosing gas engine oil for industrial use:

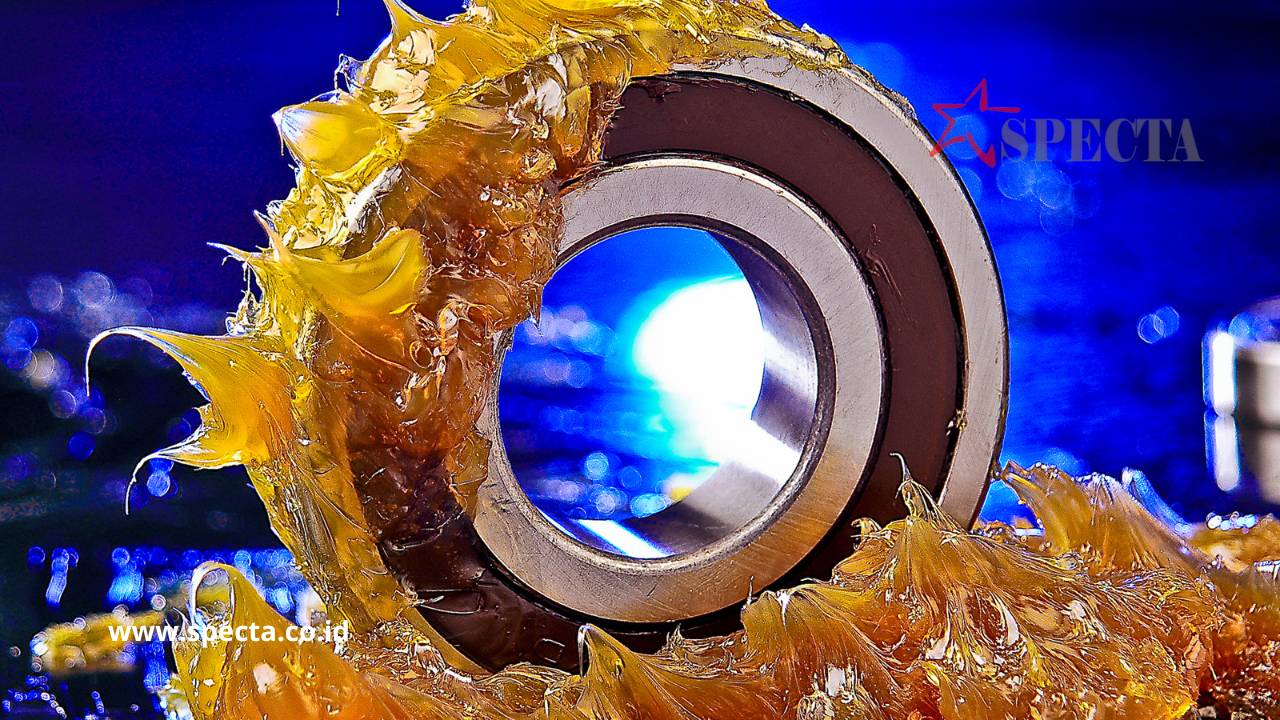

- Viscosity Grade: The viscosity grade determines how the oil flows under different temperatures. Industrial gas engines benefit from multi-grade oils that provide optimal protection regardless of temperature fluctuations.

- Compatibility with Gas Type: Consider the type of gas that the engine uses—whether natural gas, biogas, or landfill gas. Each fuel type has unique requirements for oil performance. Some fuels produce higher combustion residues that may require specific oil properties.

- Additive Packages: Additives are a significant part of the oil that help neutralize acids, reduce friction, and control deposits. Industrial gas engines require a premium blend of additives to counteract the by-products of gaseous fuel combustion.

- Operational Conditions: Industrial environments vary greatly, and each setting has its demands. Whether the engine operates in high dust conditions or in cold climates, it’s critical to choose an oil that meets these specific conditions.

Why Panaoil Gas Engine Oil Is the Best Choice for Industrial Engines

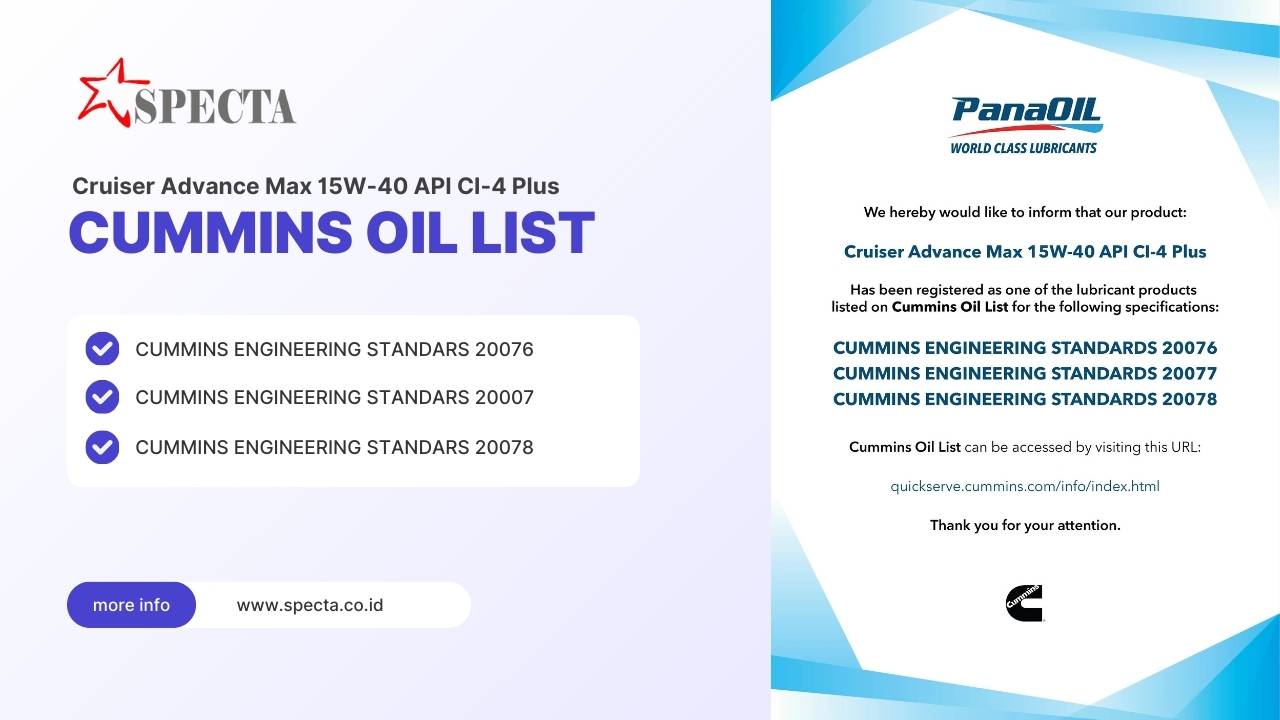

Panaoil is a trusted brand when it comes to gas engine oils. The company offers products specifically formulated to meet the high demands of industrial gas engines, making it an ideal choice for maintaining machinery efficiency.

Advantages of Panaoil Gas Engine Oil:

- Advanced Thermal Stability: Panaoil gas engine oil features enhanced thermal stability, which helps in managing the heat produced by large industrial gas engines. This ensures consistent performance under extreme temperatures.

- Oxidation and Nitration Resistance: Industrial gas engines are susceptible to oxidation and nitration, which can affect oil performance and engine parts. Panaoil gas engine oil has excellent resistance to these chemical reactions, providing extended drain intervals and reducing maintenance frequency.

- Cleaner Engines for Longer Durations: Panaoil contains effective detergents and dispersants to keep the engine clean and free from harmful deposits. This helps extend the engine’s lifespan, especially in environments where engines are continuously used.

- Compatibility with Biogas and Other Gases: The versatility of Panaoil allows it to work effectively in engines powered by natural gas, biogas, and other alternative fuels. This makes it an ideal solution for industrial facilities relying on renewable energy sources.

How Gas Engine Oil Supports Industrial Machinery

1. Improved Fuel Efficiency

Fuel efficiency is crucial for industrial operations looking to minimize operating costs. Gas engine oil is designed to lubricate engine parts effectively, which reduces the amount of energy lost due to friction. With smoother engine operation, the overall fuel consumption decreases, contributing to better cost efficiency.

2. Minimizes Engine Downtime

In industrial applications, minimizing downtime is critical to maintaining productivity. Gas engine oil, especially quality brands like Panaoil, helps ensure that engines continue to run smoothly and effectively without unexpected breakdowns. With fewer issues, maintenance schedules become predictable, and costly downtime is reduced.

3. Enhanced Lubrication for Heavy Loads

Industrial engines often operate under heavy loads, especially when driving pumps or compressors. Gas engine oil provides the necessary lubrication to ensure that engine components are adequately protected against wear, even under these challenging conditions. Using Panaoil’s specialized formulations, industries can enhance the reliability of their engines during high-load cycles.

Maintenance Tips for Industrial Gas Engines Using Gas Engine Oil

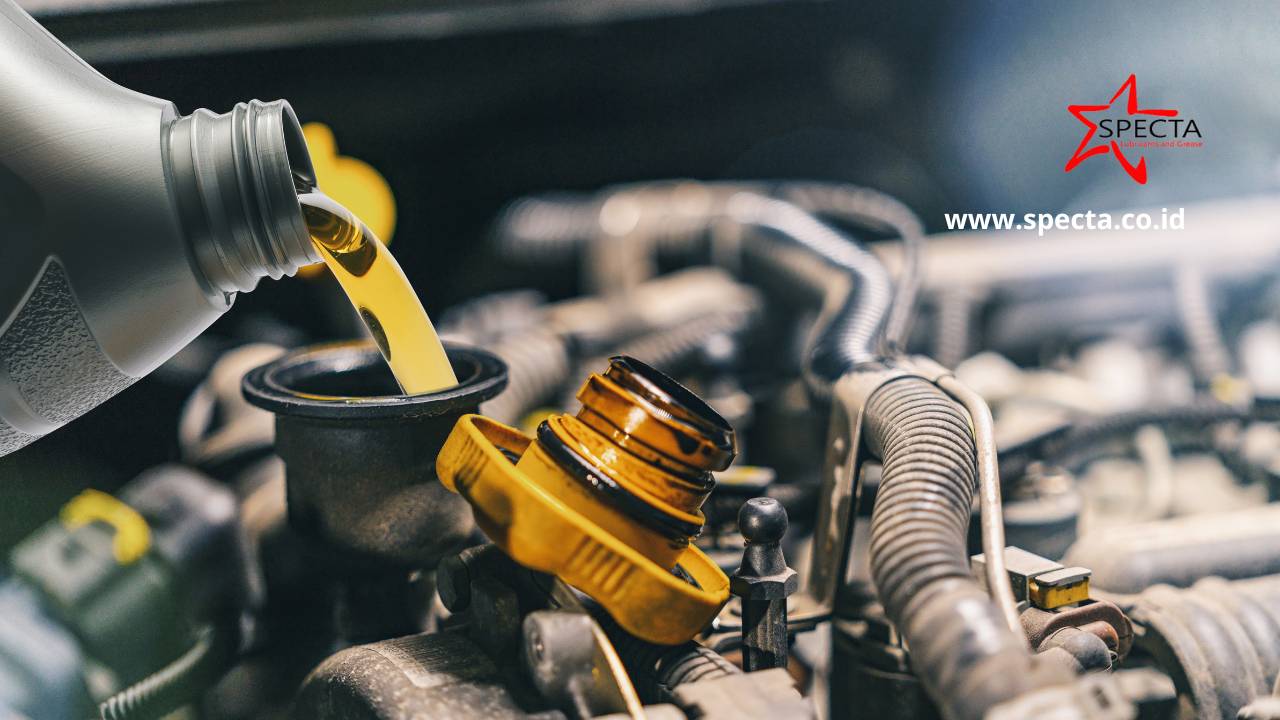

- Regular Oil Analysis: Conduct oil analysis to determine the condition of the oil and to detect any contaminants that may indicate engine issues. It allows you to plan oil changes effectively and catch potential problems early.

- Change Oil at Recommended Intervals: Follow manufacturer recommendations for changing the oil. Gas engines operating under industrial conditions may require more frequent oil changes due to continuous high loads.

- Check for Leaks and Oil Consumption: Keep an eye out for leaks and measure oil consumption. Excessive oil use or leaks can indicate internal issues that need attention before they escalate into significant problems.

- Monitor Engine Temperature: Excessively high temperatures can degrade the oil faster and affect engine components. Ensure that the cooling systems work properly and maintain a stable temperature range suitable for the oil type.

FAQs About Gas Engine Oil for Industrial Use

1. What Is the Best Type of Gas Engine Oil for Industrial Applications?

The best type of gas engine oil for industrial use is one that matches the specific engine requirements and the operational conditions. Panaoil Gas Engine Oil is highly recommended for its specialized formulation that enhances durability and thermal stability.

2. How Often Should Gas Engine Oil Be Changed in Industrial Engines?

The frequency of oil changes will depend on the engine type, load, and operational conditions. Typically, industrial gas engines require oil changes between 500 to 1,500 hours of operation. Conducting oil analysis helps in determining the best oil change interval.

3. What Happens if the Wrong Viscosity Gas Engine Oil Is Used?

Using the wrong viscosity can lead to insufficient lubrication, increased friction, and accelerated wear of engine components. It may also cause the oil to break down faster, reducing its protective properties. Always ensure the viscosity grade matches the manufacturer’s requirements.

4. Why Should I Consider Panaoil for My Industrial Gas Engines?

Panaoil Gas Engine Oil offers advanced benefits such as superior thermal stability, oxidation resistance, and compatibility with multiple gas types. Its formulation ensures that industrial engines remain efficient, clean, and require minimal maintenance.

5. Is Gas Engine Oil Suitable for Renewable Energy-Powered Engines?

Yes, gas engine oil, particularly from brands like Panaoil, is suitable for engines powered by renewable sources like biogas. It provides the necessary protection and performance features for engines using different gas types, making it versatile in renewable energy applications.

6. How Does Gas Engine Oil Contribute to Emission Control?

Gas engine oil plays a role in reducing emissions by keeping the engine clean and ensuring efficient combustion. Cleaner combustion means fewer harmful by-products and emissions, which is crucial for meeting regulatory standards in industrial settings.

Conclusion: Why Panaoil Gas Engine Oil is the Ideal Choice for Industrial Engines

Industrial machinery requires consistent, high-quality lubrication to keep operating efficiently under demanding conditions. Gas engine oil is crucial in achieving this, and choosing the right brand like Panaoil can make all the difference. With its advanced formulation, Panaoil Gas Engine Oil helps ensure optimal thermal stability, oxidation resistance, and overall durability of industrial gas engines.

To maximize efficiency, ensure regular maintenance, conduct oil analysis, and use high-quality gas engine oil like Panaoil to keep your industrial machinery running smoothly. When selecting an oil, always consider the type of engine, operational conditions, and fuel type, as these factors determine the most suitable oil for your needs.

Read more also: How to Choose the Right Industrial Oil for Your Machinery